July 6th- July 12th

Kyle/ July 26, 2020/ Artemis/ 0 comments

Amber’s Updates

Hiapo received frequency coordination from the IARU and is one document away from getting to submit all documents to the FCC step. We also started working on the ODAR parts list for Artemis.

The Mechanical Team

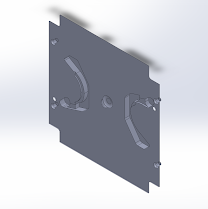

Within the past week, the mechanical team discussed Helicoil inserts for the main aluminum frame and started working on two separate deployer systems, finalized selection for structure hardware such as screws, nuts, inserts, and rods. The team also set up the ADCS testbed as well as the air bearing system and motion camera, worked on satellite deployment design as well as looking into S-band and payload development for the antenna deployer. They also are assembling and printing out CAD models??? And set up the 3D printer and began printing the prototype of the antenna deployer

The Software Team

The team started working on agent radio and looked into how to operate with XDL Micro. Also worked on agent Raspberry Pi and read up on point-to-point protocol (PPP). Worked on implementing agent PyCubed. The Agent radio is mostly complete but still needs to make a couple of changes to use the XDL Micro. In addition, the team soldered the Gumstix Tobi board and also were able to get the Gumstix to connect to the desktop machine and run shell commands. New python modules have been installed and the software notebook has been updated to include Raspberry Pi. With an addition of an HDMI- A to C cable the Raspberry Pi successfully booted. The team worked on propagator simple and were able to make progress and receive values. Furthermore, the payload script is now functional and the python CubeSat library has been restructured and rewritten.

The Avionics Team

The team created a temperature profile for the boards using the soldering oven and started the 24-hour bake. For Hiapo, the board and BOM are completed! The EAGLE schematic and board design have been uploaded to the Hiapo drive and are ready for final inspection before being sent out for manufacturing. On another note, the Mouser shipment arrived for some of the PyCubed mainboard and battery board parts. They also took inventory and double-checked/updated the PyCubed BOM to match accordingly. Finally, The board layout design, as well as the EAGLE schematic and board, have all been updated and are uploaded to the radio folder in the Hiapo drive.